Stainless Steel

- Stainless Steel

- 13-8

- 15-5

- 17-4

- 17-7

- A286

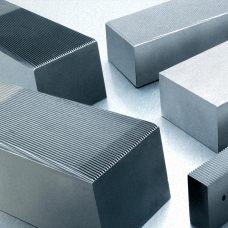

STAINLESS STEEL ALLOYS

As your stainless steel supplier, we are capable of fulfilling your required lengths and widths. Royal Emperor Metals also has a stocking program to support long term contract for your stainless steel needs.

13-8 Stainless Steel - Sheet, Plate, Bar, Forged Bar

UNS S13800, AMS 5268, AMS 5629, AMS 5864

* All Trademarks and/or Trade names are the properties of their respective owners.

13-8 Stainless Steel Specifications:

AMS 5268, AMS 5629, AMS 5864,

UNS S13800

Alloy 13-8, Alloy 13-8 PH, 13-8 PH Stainless Steel

13-8 Stainless Steel Available Forms:

13-8 Alloy Sheet, 13-8 Alloy Plate, 13-8 Alloy Bar, 13-8 Alloy Forged Bar

13-8 Stainless Steel Applications:

Aircraft Components: landing gear, structural sections, valves, shafts

Components in the petrochemical and nuclear industries

Description

Alloy 13-8 PH stainless steel is a precipitation, age hardenable stainless steel. Stainless Steel 13-8’s principal features are toughness, good resistance to general and stress corrosion cracking, and high strength that is developed by a single low temperature heat treatment.

Composition

13-8 steel is composed primarily of steel, with chromium and nickel being the other major chemical properties.

Physical Properties

Melting Point: 2560 – 2680°F (1404 – 1471°C)

Density (Condition H1000): 0.280 lbs/in3 / 7.75 g/cm3

Modulus of Elasticity in Tension: 28.3 X 106 psi / 195 GPa

Mechanical Properties

Condition: Aged (H950) Tensile Strength Minimum (psi): 220,000

Yield Strength Minimum 0.2% offset (psi): 205,000

% Elongation in 2” Typical: 10%

Hardness: Rockwell C45

Condition: Aged (H1025) Tensile Strength Typical (psi): 185,000

Yield Strength Typical 2% offset (psi): 175,000

% Elongation in 2″: 12%

Hardness: Rockwell C38

Condition: Aged (H1150) Tensile Strength Typical (psi): 135,000

Yield Strength Typical 2% offset (psi): 90,000

% Elongation in 2″: 7%

Hardness: Rockwell C30

Heat Treatment

CONDITION A–Soak at 1700 F (927 C) and cool below 60 F (16 C) for 1 hour. CONDITION RH 950- Treat Condition A material at -100 F(-73C) for 2 hours, air warm to room temperature (within 24 hours of solution treatment). Then heat cold treated material to 950 F(510 C) for 4 hours and air cool. CONDITION H950, H1000, H1050, H1100, H1150- Soak solution treated material for 4 hours at specified temperature, air cool, CONDITION H1150M- Soak solution treated material at 1400 F (760 C) for 2 hours, air cool, then re-heat to 1150 F (620 C) for 4 hours and air cool.

Corrosion Resistance

13-8’s corrosion resistance is similar to that of Type 304 Stainless in strongly oxidizing and reducing acids and in atmospheric exposures. The alloy’s level of general-corrosion resistance is greatest in the fully hardened condition and decreases slightly as the aging temperature is increased. In Condition H 950, rusting resistance is also similar to that of Type 304 Stainless.

Machinability & Forming

This is a tough machining stainless steel. Although it can be machined in all conditions, best results can be obtained in condition H1150M. Compared to type 304 stainless, speeds should be roughly 25 % lower for optimum tool life and finish.

This alloy can be formed using conventional techniques with the degree of formability being limited only by its high initial yield strength.

Forging

Soak at 2150 F(1177 C) for 1 hour prior to forging. Do not work below 1750 F(954 C). All forgings should be solution treated prior to final hardening. Air cool to room temperature after forging.

Hot & Cold Working

13-8 can be satisfactorily hot worked. Hot worked material must be solution annealed prior to hardening for reliable results. Despite its high initial yield strength, this alloy can be satisfactorily cold worked.

Royal Emperor Metals & Supply is a leading supplier of quality 13-8 Stainless Steel Sheet, 13-8 Stainless Steel Plate, 13-8 Stainless Steel Bar, 13-8 Stainless Steel Forged Bar.

All of our Alloy 13-8 PH stainless steel is ordered to specific thickness. We supply 13-8 PH stainless steel and are capable of fulfilling your required lengths and widths. California Metal & Supply Inc. also has a stocking program to support long term contract for your 13-8 PH stainless steel needs

15-5 Stainless Steel - Sheet, Plate, Bar, Forged Bar

UNS S15500, AMS 5659, AMS 5862, ASTM A564

* All Trademarks and/or Trade names are the properties of their respective owners.

15-5 Stainless Steel Specifications:

AMS 5659, AMS 5862, ASTM A564

Alloy 15-5, Alloy 15-5 PH, 15-5 PH Stainless Steel, 15-5 PH sheet, 15-5 precipitation hardened (PH) stainless steel sheet, UNS S15500

15-5 Stainless Steel Available Forms:

15-5 Alloy Sheet, 15-5 Alloy Plate, 15-5 Alloy Bar, 15-5 Alloy Forged Bar

15-5 Stainless Steel Applications: Stainless Steel Alloy 15-5 is used in industrial applications, especially for the aerospace, food service, metalworking, chemical and petrochemical industries.

Description

15-5 PH stainless steel offers high strength and hardness with excellent corrosion resistance. SS 15-5 can be age-hardened by a low temperature treatment. 15-5 PH stainless steel offers good corrosion resistance, and high strength therefore has been used for aerospace applications.

Composition

15-5 PH stainless steel includes high levels of chromium, nickel and copper. Carbon, manganese, phosphorus, sulfur, silicon and columbium plus tantalum may also be present in trace amounts, with each not exceeding 1 percent of the compositional total.

Physical Properties

Melting Point: 2560 – 2625°F (1404 – 1440°C)

Density: 0.282 lbs/in3 / 7.78 g/cm3

Modulus of Elasticity in Tension: 28.5 X 106 psi / 196 GPa

Mechanical Properties

Condition: Solution Treated (A) Tensile Strength Minimum (psi): 160,000

Yield Strength Minimum 0.2% offset (psi): 140,000

% Elongation in 2” Typical: 8%

Hardness: Rockwell C35

Condition: Aged (H1075) Tensile Strength Typical (psi): 162,000

Yield Strength Typical 2% offset (psi): 160,000

% Elongation in 2″: 12%

Hardness: Rockwell C38

Condition: Aged (H900) Tensile Strength Typical (psi): 210,000

Yield Strength Typical 2% offset (psi): 200,000

% Elongation in 2″: 9%

Hardness: Rockwell C46

Heat Treatment

15-5 is typically supplied in Condition A, and can be heat treated at a variety of temperatures and times to achieve a wide range of properties.

Corrosion Resistance

The general level of corrosion resistance exceeds that of Types 410 and 431, and is approximately equal to that of Type 17-4 PH stainless steel as indicated by laboratory tests in both strongly oxidizing and reducing media, as well as by atmospheric exposures. The general level of corrosion resistance is best in the fully hardened condition, and decreases slightly as the aging temperature is increased.

Royal Emperor Metals & Supply is a leading supplier of quality 15-5 Stainless Steel Sheet, 15-5 Stainless Steel Plate, 15-5 Stainless Steel Bar, 15-5 Stainless Steel Forged Bar.

All of our 15-5 PH stainless steel is ordered to specific thickness. We supply 15-5 PH stainless steel and are capable of fulfilling your required lengths and widths. California Metal & Supply Inc. also has a stocking program to support long term contract for your 15-5 PH stainless steel needs.

17-4 Stainless Steel - Sheet, Plate, Bar, Forged Bar

UNS S17400, AMS 5643, AMS 5622, AMS 5604

* All Trademarks and/or Trade names are the properties of their respective owners.

17-4 Stainless Steel Specifications:

AMS 5643, AMS 5622, AMS 5604

Alloy 17-4, Alloy 17-4 PH, 17-4 PH Stainless Steel, UNS S17400

17-4 Stainless Steel Available Forms:

17-4 Alloy Sheet, 17-4 Alloy Plate, 17-4 Alloy Bar, 17-4 Alloy Forged Bar

17-4 Stainless Steel Applications: Stainless Steel Alloy 17-4 is used in industrial applications, especially for the aerospace, nuclear energy, and chemical processing industries.

Description

17-4 PH Stainless Steel features good corrosion resistance, hardness, toughness and strength. 17-4 PH Stainless Steel is a very widely used precipitation hardened alloy with a toughness especially suited for industrial applications.

Composition

Carbon: 0.07 max

Manganese: 1.00 max

Phosphorus: 0.040 max

Sulfur: 0.030 max

Silicon: 1.00 max

Chromium: 15.00 – 17.50

Nickel: 3.00 – 5.00

Copper: 3.00 – 5.00

Iron: Balance

Physical Properties

Melting Point: 2560 – 2625°F (1404 – 1440°C)

Density: 0.282 lbs/in3 / 7.8 g/cm3

Modulus of Elasticity in Tension: 28.5 X 106 psi / 197 GPa

Mechanical Properties

Condition: Solution Treated (A) Tensile Strength Minimum (psi): 160,000

Yield Strength Minimum 0.2% offset (psi): 145,000

% Elongation in 2” Typical: 5%

Hardness: Rockwell B85

Condition: Hardened + Aged (TH1050) Tensile Strength Typical (psi): 200,000

Yield Strength Typical 2% offset (psi): 185,000

% Elongation in 2″: 8%

Hardness: Rockwell C35

Condition: Aged (H1075) Tensile Strength Typical (psi): 175,000

Yield Strength Typical 2% offset (psi): 165,000

% Elongation in 2″: 8%

Hardness: Rockwell C37

Condition: Aged (H900) Tensile Strength Typical (psi): 210,000

Yield Strength Typical 2% offset (psi): 200,000

% Elongation in 2″: 7%

Hardness: Rockwell C45

Heat Treatment

17-4 is typically supplied in Condition A, and can be heat treated at a variety of temperatures and times to achieve a wide range of properties.

Corrosion Resistance

The corrosion resistance of 17-4 PH is comparable to that of Type 304 stainless Steel in most media and superior to that of the hardenable 400 series stainless steels. The alloy exposed to seacoast atmosphere will gradually develop overall light rusting and pitting in all heat-treated conditions. In common with other stainless steels, 17-4 material is subject to crevice attack if exposed to stagnant seawater for any length of time.

Royal Emperor Metals & Supply is a leading supplier of quality 17-4 Stainless Steel Sheet, 17-4 Stainless Steel Plate, 17-4 Stainless Steel Bar, 17-4 Stainless Steel Forged Bar.

All of our 17-4 PH stainless steel is ordered to specific thickness. We supply 17-4 PH stainless steel and are capable of fulfilling your required lengths and widths. California Metal & Supply Inc. also has a stocking program to support long term contract for your 17-4 PH stainless steel needs.

17-7 Stainless Steel - Sheet, Plate, Bar, Forged Bar

UNS S17700, AMS 5644, AMS 5528, AMS 5568

* All Trademarks and/or Trade names are the properties of their respective owners.

17-7 Stainless Steel Specifications:

AMS 5644, AMS 5528, AMS 5568

Alloy 17-7, UNS S17700

17-7 Stainless Steel Available Forms:

17-7 Alloy Sheet, 17-7 Alloy Plate, 17-7 Alloy Bar, 17-7 Alloy Forged Bar

17-7 Stainless Steel Applications: Stainless Steel Alloy 17-7 is used for intricate parts due to its low distortion in heat treatment. It finds uses in variety of springs and washers, chemical processing equipment, heat exchangers, power boilers, superheater tubes, and components used in high-strength/high-temperature conditions.

Description

17-7 PH stainless steel is a precipitation-hardening stainless steel. SS 17-7 offers good corrosion resistance, good formability, and high strength therefore has been used for aerospace applications.

Composition

17-7 PH stainless steel includes high levels of chromium, nickel and aluminum. In addition to these elements, iron makes up the bulk of the steel’s composition. Carbon, manganese, phosphorus, sulfur and silicon may also be present in trace amounts, not exceeding 1 percent of the compositional total.

Physical Properties

Melting Point: 2550 – 2640°F (1400 – 1450°C)

Density: 0.282 lbs/in3 / 7.8 g/cm3

Modulus of Elasticity in Tension (RH 950 & TH 1050): 29.6 X 106 psi / 204 GPa

Mechanical Properties

Condition: Annealed Tensile Strength Minimum (psi): 130,000

Yield Strength Minimum 0.2% offset (psi): 40,000

% Elongation in 2” Typical: 35%

Hardness: Rockwell B85

Condition: Hardened + Aged (TH1050) Tensile Strength Typical (psi): 200,000

Yield Strength Typical 2% offset (psi): 185,000

% Elongation in 2″: 9%

Hardness: Rockwell C40

Condition: Hardened, Cryogenic Quench + Aged (RH950) Tensile Strength Typical (psi): 235,000

Yield Strength Typical 2% offset (psi): 220,000

% Elongation in 2″: 6%

Hardness: Rockwell C48

Condition: Cold Rolled/Worked + Aged (CH900) Tensile Strength Typical (psi): 265,000

Yield Strength Typical 2% offset (psi): 260,000

% Elongation in 2″: 2%

Hardness: Rockwell C49

Heat Treatment

This material requires three essential steps in heat treating:

1) Austenite conditioning.

2) Cooling to transform the austenite to martensite.

3) Precipitation hardening to Condition TH 1050 or RH 950.

To obtain the highest mechanical properties from the alloy, Condition A material is transformed to martensite the mill by cold reduction to Condition C. Hardening to Condition CH 900 is accomplished with a single, low-temperature heat treatment.

Corrosion Resistance

Corrosion resistance in Condition TH 1050 and RH 950 is generally superior to that of the standard hardenable chromium types of stainless steel such as Types 410, 420 and 431, but is not quite as good as chromium-nickel Type 304. Corrosion resistance in Condition CH 900 approaches that of Type 304 in most environments.

Formability

In Condition A, the alloy can be formed comparably to Type 301. It work hardens rapidly and may require intermediate annealing in deep drawing or in forming intricate parts. Springback is similar to that of Type 301. This alloy is extremely hard and strong in Condition C. Therefore, fabrication techniques for such material must be used.

Weldability

The precipitation hardening class of stainless steel is generally considered to be weldable by the common fusion and resistance techniques. Special consideration is required to achieve optimum mechanical properties by considering the best heat-treated conditions in which to weld and which heat treatments should follow welding. This particular alloy is generally considered to have poorer weldability compared to the most common alloy of this stainless class, 17-4 PH stainless steel. A major difference is the high Al content of this alloy, which degrades penetration and enhances weld slag formation during arc welding. Also, the austenite conditioning and precipitation hardening heat treatments are both required after welding to achieve high strength levels. When a weld filler is needed, 17-7 PH is most often specified.

Royal Emperor Metals & Supply is a leading supplier of quality 17-7 Stainless Steel Sheet, 17-7 Stainless Steel Plate, 17-7 Stainless Steel Bar, 17-7 Stainless Steel Forged Bar.

All of our 17-7 PH stainless steel and stainless steel plate is ordered to specific thickness. We supply 17-7 PH stainless steel and 17-7 PH stainless steel plate and are capable of fulfilling your required lengths and widths. Royal Emperor Metals & Supply Inc. also has a stocking program to support long term contract for your 17-7 PH stainless steel needs.

A286 - Sheet, Plate, Bar, Forged Bar

UNS S66286, AMS 5525, AMS 5731, AMS 5732, AMS 5737

* All Trademarks and/or Trade names are the properties of their respective owners.

A-286 Specifications: AMS 5525, AMS 5731, AMS 5732, AMS 5737

A-286 Stainless Steel Alloy, UNS S66286, A-286 Stainless, Alloy A-286 Stainless Steel, A-286 Alloy, Grade 660, ASTM A638 (VO1.03), A453 (VO1.01), 660B

A-286 Available Forms: A-286 Stainless Steel Sheet, A-286 Stainless Steel Round Bar, A-286 Stainless Steel Plate, A286 Stainless Steel Forged Bar

A-286 Applications: A286 is used in aircraft and industrial gas turbine, super-charger components, jet engines, blades, wheels, castings, frames, fasteners, sockets, flange nuts, screws, afterburner parts.

Description

Alloy A286 Stainless Steel is designed for applications requiring high strength and good corrosion resistance. An advantage of A286 is that it can be precipitation hardened and strengthened by heat treatments.

Royal Emperor Metals & Supply is a leading supplier of quality A286 Stainless Steel Sheet, A286 Stainless Steel Plate, A286 Stainless Steel Bar, A286 Stainless Steel Forged Bar.

All of our A286 Stainless Steel is ordered to specific thickness. We supply A286 Stainless Steel and are capable of fulfilling your required lengths and widths. Royal Emperor Metals & Supply Inc. also has a stocking program to support long term contract for your A286 needs.